Material strength Laboratory

Explore mechanical joining techniques for more reliable multi-material structures!

Multi-material structures have been promoted in the field of transport equipment including cars, trains and airplanes. Multi-material structures can design lightweight and high-strength structures by using various materials appropriately. Those structures need highly-reliable techniques to join dissimilar materials like dissimilar metals and resin & metals. To realize multi-material structures, we focus on research of mechanical joint methods such as bolted joint including bolt & nut and high-speed nailing joint to drive nails into metals with high speed.

- Faculty Name

- HASHIMURA, Shinji

- Keyword

- Metal fatigue,Mechanical joining technologies,Machine elements,Bolted joints,Automobiles,Aerospace

- Laboratory location

- Research Building TOYOSU Campus 4F 04C32-a

This lab is for this SDG activity:

STUDY FIELDS

- Mechanics of Materials

- Strength of Materials

- Mechanical Design Engineering

- Tribology

FOR SOCIETY

Our study outcomes are used in a wide range of mechanical structures and help to enhance weight reduction and reliability of transport equipment assembly including bullet trains and cars. We have been contributing to improvement of reliability of mechanical joint techniques indispensable for coming multi-material age.

RESEARCH THEMES

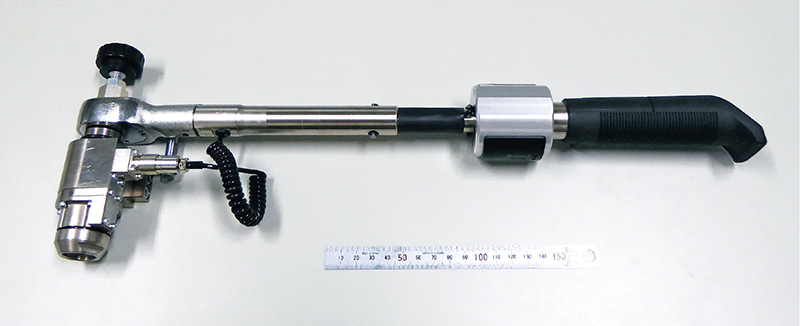

- Study of high-speed nailing joint

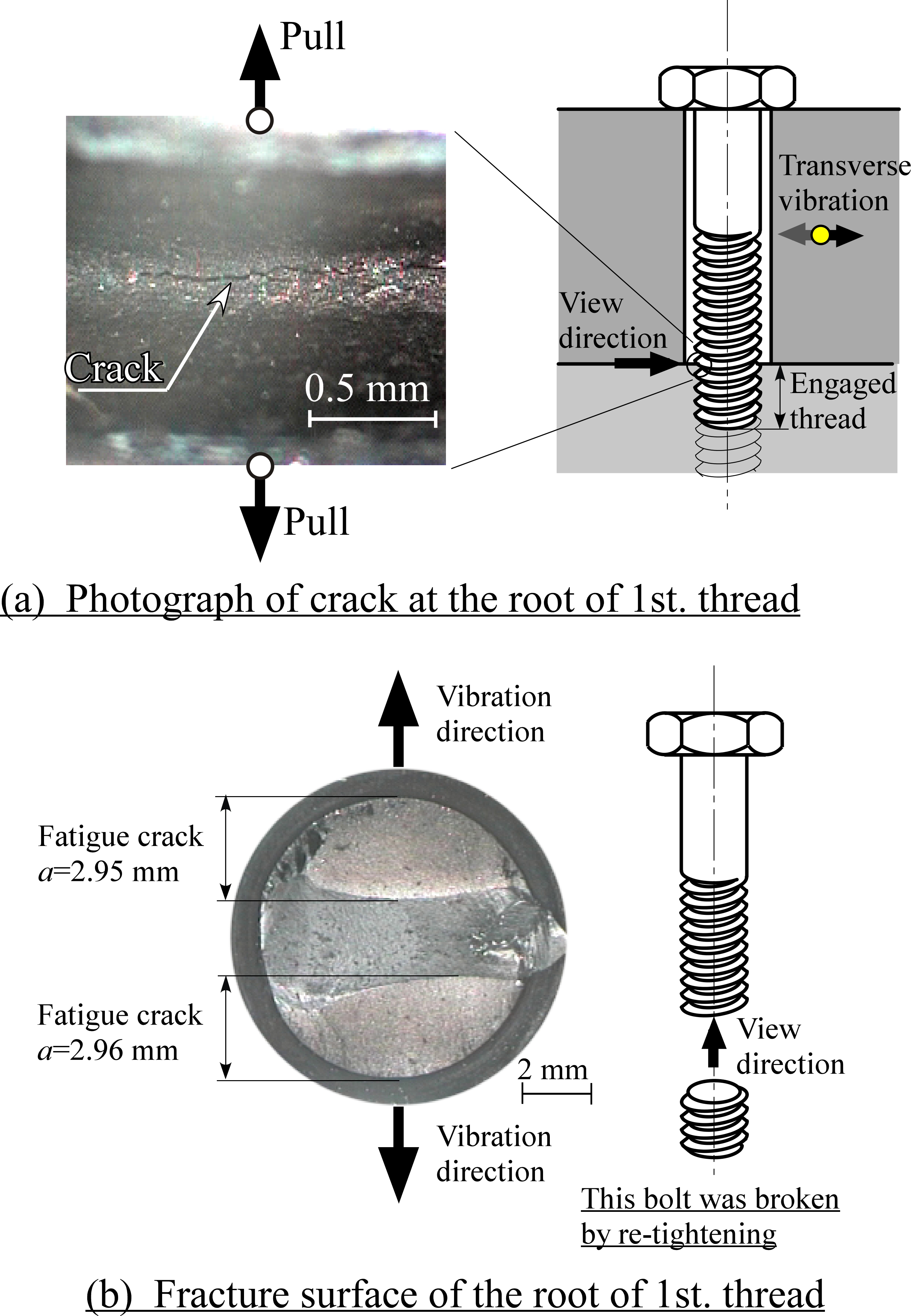

- Study of New Loosening Mechanism for thin plate bolted joints

- Research on the causes of variations in stiffness and strength of bolted joints

- Study to control clamp force of bolted joints