The Sound of Water: New Refining Technique Makes Cheaper Superconductors A Reality

2022/07/15

- Research

Researchers improve the performance of superconductors while reducing the cost using a novel refining technique for boron

Magnesium diboride (or MgB2) ceramic superconductors have garnered interest owing to their ease of fabrication, light weight, and low cost. However, a cheap and efficient technique for boron refinement is required before MgB2 superconductors can be produced widely for use. To this end, scientists from Shibaura Institute of Technology have developed a novel technique to refine boron via ultrasonication. Their method provides a rapid and cost-effective means to produce MgB2 for superconductor production.

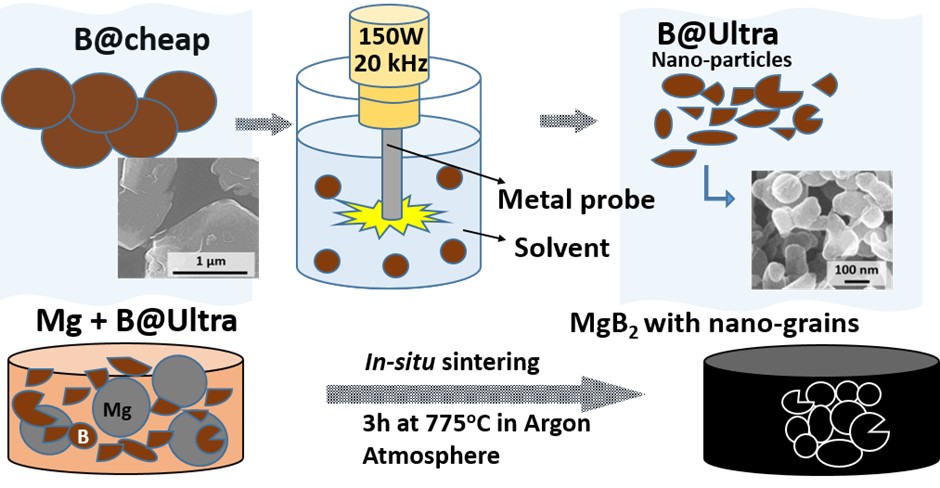

Title:Schematic view of the ultrasonication method

Caption:A schematic view of ultrasonication, depicting the process of refining large boron particles to obtain nano-grained sintered MgB2 bulk.

Credit:Muralidhar Miryala from SIT, Japan

License type:CC BY-NC-ND 2.0

Image link:https://www.sciencedirect.com/science/article/pii/S0272884222021162

Previous research has shown that using nanoscale boron to make MgB2 results in better magnetic characteristics. However, commercial nanoscale boron is expensive. Ball milling, a popular method for refining boron introduces impurities which hinder the superconductor’s performance. Thus, there is a need for a low-cost method for the nanoscale refining of boron. Now, in a paper published in Ceramics International (version available online on 14 June 2022), a team of researchers from Shibaura Institute of Technology (SIT), led by Professor Muralidhar Miryala, solved this problem by outlining an all-new, low-cost, and efficient method for refining boron.

The team used a technique called ultrasonication, a technique that employs ultrasound waves to agitate particles in a sample. First, they placed commercially available crystalline boron in distilled water. This was then subjected to ultrasonic sound waves of 20 kHz. The researchers subjected the crystalline boron to the ultrasonic treatment for varying periods of time to see which time period would be ideal. The resulting superconductor samples were checked for impurities, microstructure, and magnetic properties.

“We found that our samples of MgB2 were around 95% pure, which is much higher than the ball milling method that only produced 75% purity. The samples had a refined microstructure and had a 35% improvement than other methods. All of this was achieved with only 30 minutes of ultrasonic treatment”, says Prof. Miryala. This makes this new method of ultrasonication using distilled water extremely efficient at refining boron without having to use expensive materials. It brings down the cost of making MgB2 superconductors while also improving their magnetic characteristics.

According to Prof. Miryala, “Although ultrasonication as a method has been explored before for refining, previous attempts have used ethanol or hexane. This increases the cost of the process. The use of distilled water brings down the cost while still being as good or even better than the previous mediums.”

Overall, this study represents a huge step forward in making superconductors easily available for commercial purposes in devices. In addition, the study also brings into focus the ultrasonication technique, which is currently in its early stages of development. “This new technique will create more avenues of research. Other researchers can work on the optimization of this method to bring out its complete potential as well as apply this technique in their respective fields,” comments Prof. Miryala.

The researchers are confident that their findings will make cheap superconductors a reality soon enough!

Reference

| Title of original paper: | Novel ultra-sonic boron refinement in distilled water for cost-efficient fabrication of MgB2 bulk ceramic superconductors |

| Journal | Ceramics International |

| DOI: | 10.1016/j.ceramint.2022.06.115 |

Funding Information

This study was partly supported by Shibaura Institute of Technology (SIT) International Research Center for Green Electronics and Grant-in-Aid FD research budget code: 721MA56383.Contact

Planning and Public Relations Section

3-7-5 Toyosu, Koto-ku, Tokyo 135-8548, Japan (2F the Centennial Main Building, Toyosu Campus)

TEL:+81-(0)3-5859-7070 / FAX:+81-(0)35859-7071

E-mail:koho@ow.shibaura-it.ac.jp