Towards Carbon Neutrality: New Synthesis Method Yields Superior Membrane for Carbon Capture and Storage

2021/12/15

- Research

Scientists develop new method of synthesizing a promising membrane with superior performance during CO2 removal from industrial emissions

Carbon capture and storage, a key way of reducing CO2 concentrations in emissions, involves separating out CO2 from a gaseous mixture using a membrane. Thus, scientists have been directing efforts towards improving these membranes. In a new study, a team from Japan presents a novel method of synthesizing a promising membrane on a novel silica substrate, called Si-CHA, which can make the membrane twice as permeable to CO2 than those grown using existing methods.

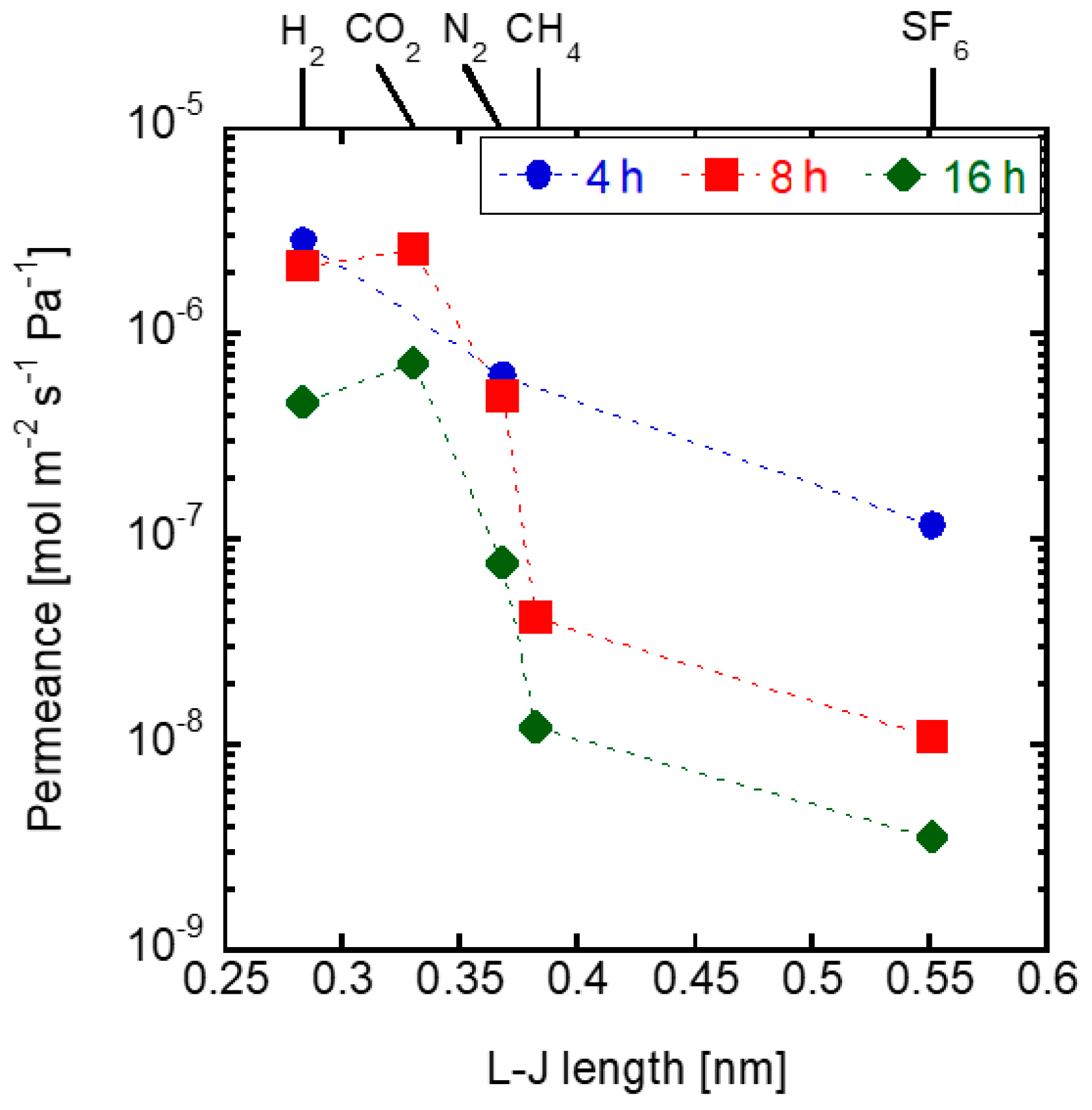

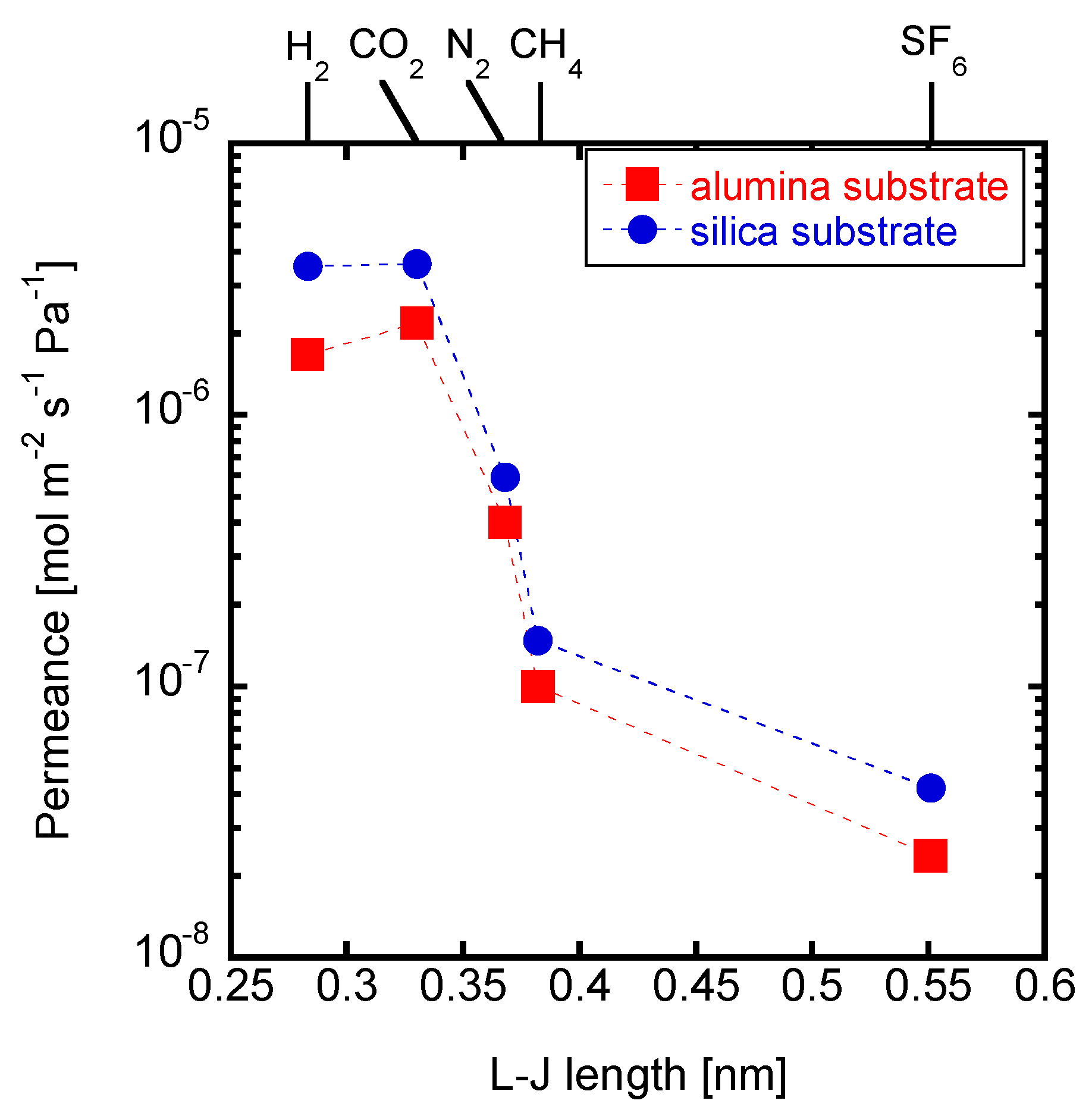

Title:Single gas permeances for various synthesis times and substrates

Caption:(Top)Highest CO2 permeance was achieved for the synthesis time of 8 hours under 150°C. (Bottom) The CO2 permeance of the membrane produced on a silica substrate

was higher than that of similar thickness produced on an alumina substrate.

Credit: Figueiredo et al. Membranes 2021, 11(12), 926;https://doi.org/10.3390/membranes11120926

Usage restrictions:Everyone is free to re-use the published material if proper accreditation/citation of the original publication is given. No special permission is required to reuse all or part of article published by MDPI, including figures and tables.

As part of the efforts to meet the net zero emissions goal, researchers worldwide are exploring ways of removing atmospheric carbon dioxide (CO2) and the CO2 in industrial emissions. One effective way is carbon capture and storage (CCS).

In CCS, membranes separate CO2 from other gases in a mixture. The physical properties of the membrane, such as its porosity, key to the efficiency of the process. Thus, efforts to improve CCS technology have been focused on improving the separation membranes. Recently, a particular membrane, Si-CHA, has gained attention as a promising option for separating CO2 from methane (CH4), another greenhouse gas that is also useful as a source of energy in a variety of industries. Si-CHA is a crystal that is largely comprised of eight-membered silicon (Si) rings which create pores of 0.38 nm diameter. This is ideal for letting CO2 molecules (0.33 nm) pass through, while holding back CH4 molecules (0.38 nm) and other larger molecules.

The most common methods to synthesize Si-CHA membranes with uniform porosity is to grow a secondary layer of the crystal over a primary parent layer coated on a substrate. The compositions of the parent layer and substrate determine how effective the resultant membrane will be. Unfortunately, there is presently no method to synthesize an efficient enough membrane for industrial use (in terms of porosity, scalability, and stability at high temperatures).

Now, in a new study published in Membranes, scientists from Japan have developed a new method to synthesize a pure Si-CHA membrane showing much higher CO2 separation performance than Si-CHA membranes developed using existing methods. This could be a first step to overcoming the barriers to its widespread use in industry.

The key to this achievement, as lead scientist Dr. Mikihiro Nomura from Shibaura Institute of Technology (SIT) explains, is to use a porous silica substrate instead of the conventional alumina substrate to grow the crystal. ‘’Usually, Si-CHA membranes are synthesized on porous alumina substrates with a layer of Si-CHA, as this method increases the mechanical strength of the resultant membrane,”he says. “However, the aluminum from the alumina substrates dissolve into the layer of CHA, reducing the pore sizes, and consequently, preventing as much CO2 from passing through the resultant membrane as would otherwise have been possible. Using a silica substrate eliminates this problem and improves CO2 separation efficiency.’’

Through experimentation under various synthesis conditions, the scientists optimized the compositions of the parent gel and substrate to obtain the membrane with the highest CO2 separation performance for a CO2/CH4 gas mixture. They also compared the performance of their membrane with those of Si-CHA membranes produced over alumina substrates.

They found that for a water to silica ratio of 4.2 in the parent gel, the viscosity (flowability) of the parent gel was just right and the smoothest membrane was created. But smoothest does not mean best in terms of CO2 permeability. A parent gel with a water to silica ratio of 4.6 coated on a porous silica substrate and left undisturbed at 150°C for 8 hours yielded a membrane with twice as high a permeability as a membrane of a similar thickness synthesized on a porous alumina substrate.

Further, the conditions needed to develop this membrane of similar thickness on an alumina substrate were 170°C and 70 hours, indicating that silica substrates potentially allowed for much better results with much milder synthesis conditions.

This is the first study to achieve effective Si-CHA membranes on a silica substrate and therefore, while it is providing key information to build upon, much research remains to be done before this synthesis method itself can be taken to industry. But Dr. Nomura is hopeful and believes that “one day this technology will be developed enough to capture CO2 sufficiently to maintain a carbon neutral society and reduce the weather fluctuations caused by global warming.”

Reference

| Title of original paper: | Development of Pure Silica CHA Membranes for

CO2 Separation |

| Journal | Membranes |

| DOI: | 10.3390/membranes11120926 |

Funding Information

This study received no external funding.Contact

Planning and Public Relations Section

3-7-5 Toyosu, Koto-ku, Tokyo 135-8548, Japan (2F the Centennial Main Building, Toyosu Campus)

TEL:+81-(0)3-5859-7070 / FAX:+81-(0)35859-7071

E-mail:koho@ow.shibaura-it.ac.jp