Making Waves: A Contactless Way to Detect Damage in Transparent Materials

2021/09/29

- Research

Scientists develop a convenient approach to spot microscopic scratches on transparent surfaces using a laser and a polarization camera

Existing methods to detect microscopic scratches and imperfections on transparent materials are costly and time-consuming. To tackle this problem, researchers from Shibaura Institute of Technology and Photron Limited, Japan, developed a novel non-contact, non-destructive approach leveraging laser-induced plasma shockwaves and mechanical vibrations detectable by a high-speed polarization camera. Their strategy could pave the way to convenient and inexpensive quality control schemes for mass-production of high-quality transparent surfaces, with applications in smartphones, tablets, and solar panels.

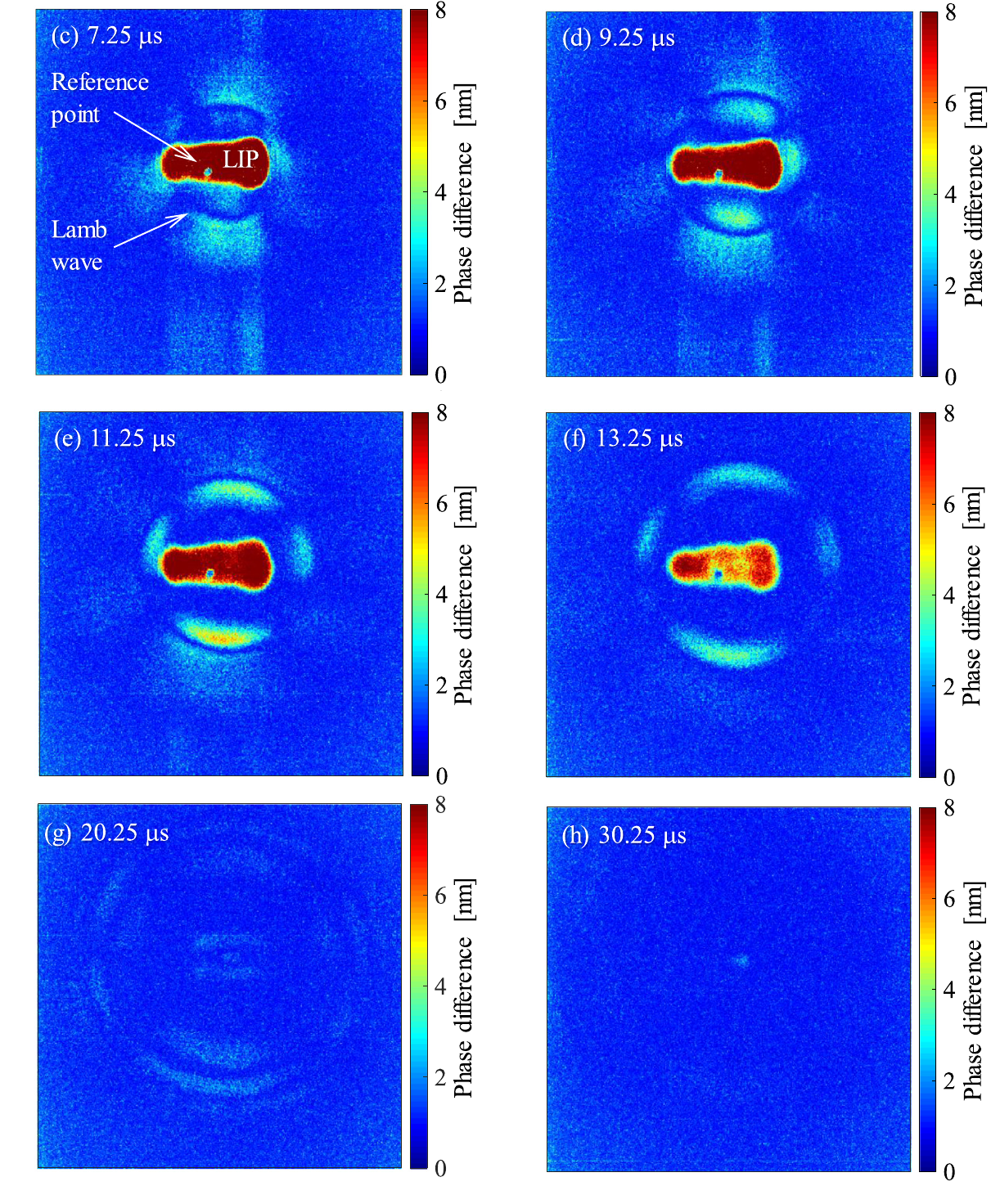

Title: Propagation of S0 mode Lamb waves in a transparent plate

Caption: Researchers from Japan used a high-speed polarization camera to capture Lamb waves on a transparent plate produced by shock waves from a laser-induced plasma, obtaining information on scratches and surface imperfections on the order of several dozen micrometers.

Credit: Prof. Naoki Hosoya fromSIT

Usage restrictions: Used under Creative Commons LicenseCC-BY-NC-ND-4.0

One attractive approach to scanning for damages on materials is using “Lamb waves.” Named after the British mathematician Sir Horace Lamb, these are elastic waves generated in solid plates following an appropriate mechanical excitation. Because the propagation of Lamb waves is affected by surface damage (such as scratches), they can be leveraged to ensure that the scanned material is free from imperfections. Unfortunately, the generation and subsequent measurement of Lamb waves on transparent materials are not straightforward.

While laser-based techniques exist for generating Lamb waves in a contactless manner, the laser parameters need to be carefully calibrated for each material to avoid causing damage. Moreover, existing approaches do not generate Lamb waves of sufficient amplitude; as such, repeated measurements have to be conducted and averaged to get reliable data, which is time-consuming. As for measuring the generated Lamb waves, no existing technique can quickly detect and use them to look for submillimeter-scale damage on transparent surfaces.

To address these issues, a research team led by Professor Naoki Hosoya from Shibaura Institute of Technology and Takashi Onuma from Photron Limited, Japan, developed a novel framework for the generation and detection of “S0 mode” (zero-order symmetrical mode) Lamb waves in transparent materials. Their approach is presented in a paper recently published online in the journal Optics and Lasers in Engineering.

First, the team had to find a convenient technique to generate Lamb waves without damaging the sample. To this end, they leveraged an approach that they had used successfully in other endeavors to generate mechanical oscillations in a contactless way: laser-induced plasma (LIP) shock waves. To put it simply, LIP can be generated by focusing a beam of high-energy laser on a tiny volume of gas. The energy of the laser energizes the gas molecules and causes them to ionize, creating an unstable “plasma bubble” close to the material’s surface. “The plasma bubble expands to its surroundings at super high speeds, generating a shock wave that is used as the excitation force to produce Lamb waves on the target structure,” explains Prof. Hosoya.

Next, the researchers needed to measure the generated waves. They achieved this by using a high-speed polarization camera, which, as the name implies, can capture the polarization of the light traveling through the transparent sample. This polarization contains information directly related to the material’s mechanical stress distribution, which, in turn, reflects the propagation of Lamb waves.

To put their strategy to the test, the team created microscopic scratches on a few flat, transparent polycarbonate plates and compared the propagation of Lamb waves on damaged and pristine samples. As expected, the scratches caused noticeable differences in the stress distribution of the plates as the waves propagated over the damaged areas, demonstrating the potential of this novel approach by detecting scratches measuring only several dozen micrometers.

While the findings are exciting, further studies are warranted to gain a more in-depth understanding of their strategy and its limits. Prof. Hosoya says, “The effects of the damage size or type, the camera lens magnification, and the properties of the transparent sample on the detectable defect size limit of our method needs to be verified as part of future works.”

Hopefully, this ingenious non-contact, non-destructive damage detection scheme will help reduce the production costs of high-quality transparent materials.

Reference

| Title of original paper: | Measurements of S0 mode Lamb waves using a high-speed polarization camera to detect damage in transparent materials during non-contact excitation based on a laser-induced plasma shock wave |

| Journal | Optics and Lasers in Engineering |

| DOI: | 10.1016/j.optlaseng.2021.106770 |

Funding Information

This study was supported by the Japan Society for the Promotion of Science under the Grants-in-Aid for Scientific Research programs (Grant No. Grant No. JP21H01279, JP17K18858, JP16H04291, and JP19H02088).Contact

Planning and Public Relations Section

3-7-5 Toyosu, Koto-ku, Tokyo 135-8548, Japan (2F the Centennial Main Building, Toyosu Campus)

TEL:+81-(0)3-5859-7070 / FAX:+81-(0)35859-7071

E-mail:koho@ow.shibaura-it.ac.jp