Fabricating MgB2 Superconductors Using Spark Plasma Sintering and Pulse Magnetization

2021/09/22

- Research

New research suggests that highly dense MgB2 bulks have improved mechanical and superconducting properties

Magnesium diboride (MgB2) has the potential to be affordable and widely produced superconductors for various applications. However, its porous nature limits its superconducting properties. Recently, a multi-national team of scientists used spark plasma sintering, a high-pressure technique to fabricate highly dense, non-porous MgB2 bulks that can withstand larger forces and have an enhanced ability to hold and trap a magnetic field, paving the way for the development of super-magnets for lightweight portable applications.

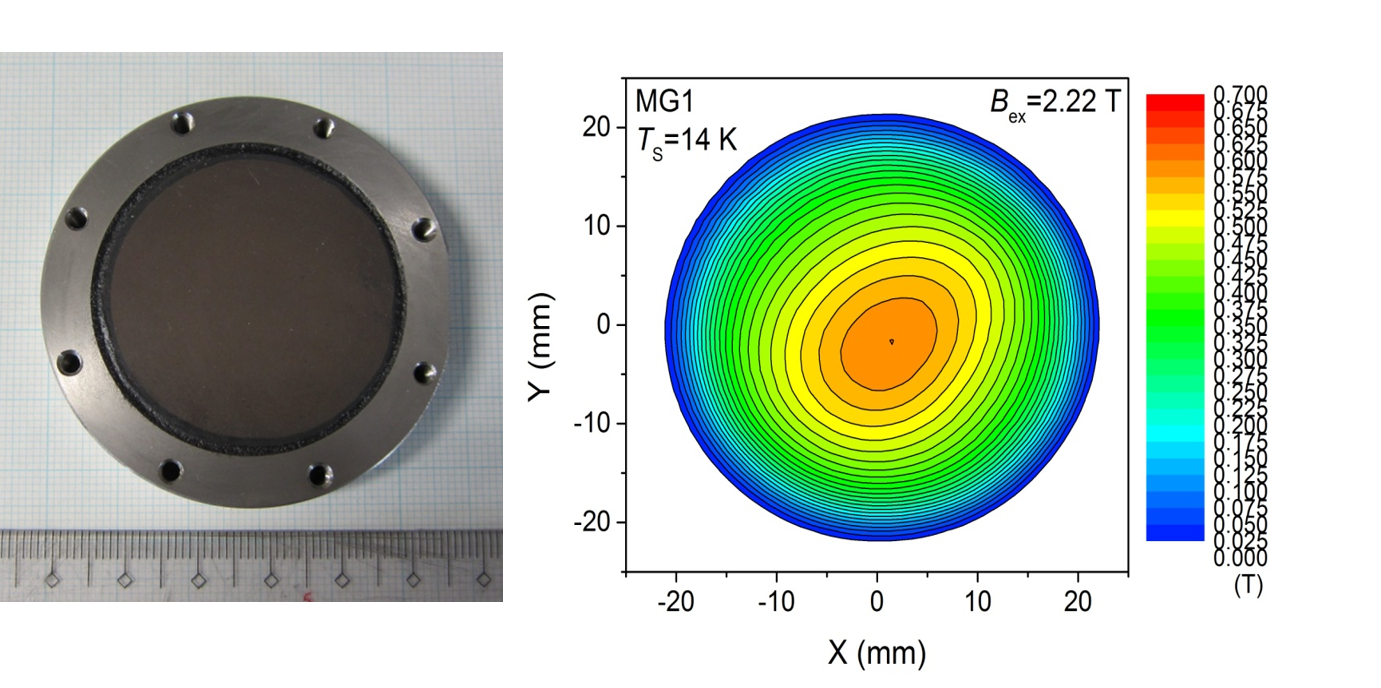

Title: Large spark plasma sintered bulkMgB2 with Hastelloy supporting ring (left) and uniform trapped field (right)

Caption: Using commercially available MgB2, the spark plasma sintering process produced a highly dense bulk, 40 mm in size, at 50 MPa and 1150°C, which had a packing fraction of 99.8 % and uniform trapped field characteristics perfect for bio-medical applications.

Credit: Muralidhar Miryala from SIT

Usage restrictions: Cannot be reused without permission

MgB2 superconductors are non-toxic, lightweight materials that can be fabricated by simple sintering processes and have current densities similar to that of conventional metallic superconductors. These properties make them suitable for applications that require cheap and lightweight superconductors such as space applications and electric machines. However, the sintering of MgB2 superconductors is performed at ambient pressures, and it results in a highly porous material that has less than optimal superconducting properties. More specifically, the porous nature of the superconductor limits the magnetic field it can trap and hold.

Now in a study published in Materials Science and Engineering: B, researchers from Shibaura Institute of Technology, Japan, enhanced the trapped magnetic field in bulk MgB2superconductors by fabricating highly dense, non-porous MgB2 bulks. Using spark plasma sintering (SPS), the researchers heated commercially available MgB2 powder with pulsed electrical current at high pressures of 50 MPa. The results were fascinating: “It is the first study in which large, 40 mm diameter MgB2 bulks with 99.8% packing ratio were fabricated via SPS,” explains Prof. Muralidhar Miryala, who led the study.

The prepared sample was of similar quality to those prepared by conventional sintering methods and had very little impurities. The high packing density was found to improve the current density and the strength of the material. On comparing their samples with dense bulks prepared via an alternative high pressure hot isostatic pressing (HIP) technique, the researchers found that the SPS bulks displayed superior strengths and had bending strengths eight times that of the HIP processed bulks.

A similar improvement in trapped field (TP) performance was noticed in the highly dense samples where their increased current density enhanced their ability to trap and hold magnetic fields. On examining the TP performance by magnetizing the samples and measuring the TP at temperatures of 14 and 20 K, the researchers found that the MgB2 bulk showed high TP for external magnetic fields up to 1.6 tesla. However, when large external magnetic fields were applied, the poor thermal conductivity of the material caused the material to overheat and the TP value to drop.

Despite its thermal limitations, the highly dense MgB2 superconductors are a significant improvement over the conventionally sintered counterparts. Commenting on the importance and novelty of their findings, Prof. Miryala explains: “The large SPS MgB2 bulks produced this way can have wide applications as superconductors and our study also paves the way for further enhancing and realizing the commercialization of these superconductors.”

Indeed, space exploration and electric transport, which necessitate cheaper, lighter, and more affordable superconductors, may soon be made more efficient using these impressive MgB2 superconductors.

Reference

| Title of original paper: | Complex Pulse Magnetization Process and Mechanical Properties of Spark Plasma Sintered Bulk MgB2 |

| Journal | Materials Science and Engineering: B |

| DOI: | 10.1016/j.mseb.2021.115390 |

Funding Information

This study was partly supported by Shibaura Institute of Technology (SIT) International Research Center for Green Electronics and Grant-in-Aid FD research budget code: 721MA56383.About Professor Muralidhar Miryala

Dr. Muralidhar Miryala is a Professor at the Graduate School of Science and Engineering and Board of Councilor at Shibaura Institute of Technology (SIT). He is an active researcher in solid state physics and material science with a focus on high temperature superconductivity. He has published over 500 research items including patents, books, review-articles, articles etc., He has received several awards for his research contributions, including the prestigious 2021 Pravasi Bharatiya Samman Award by the President of India.

Contact

Planning and Public Relations Section

3-7-5 Toyosu, Koto-ku, Tokyo 135-8548, Japan (2F the Centennial Main Building, Toyosu Campus)

TEL:+81-(0)3-5859-7070 / FAX:+81-(0)35859-7071

E-mail:koho@ow.shibaura-it.ac.jp