Revolutionizing Catalyst Synthesis for Metal–Air Batteries

- Research

Researchers develop a novel solution plasma approach for the facile production of highly efficient, low-cost catalysts for clean energy applications

Addressing the urgent demand for clean energy, Japanese researchers utilized a single-step solution plasma process to synthesize high-performing, cost-effective, bifunctional catalysts for metal–air batteries. Their cobalt-tin hydroxide/carbon composites rival traditional platinum- and ruthenium-based materials in both performance and long-term stability. This breakthrough significantly lowers manufacturing costs and enhances the scalability of next-generation batteries, poised to accelerate the transition away from fossil fuels.

Due to the intense global impact of fossil fuel overuse on air quality and climate, the search for advanced clean energy solutions has become critical. Metal–air batteries offer a game-changing alternative, holding the potential to replace combustion engines in various applications. By electrochemically converting oxygen from the air into power, these batteries achieve theoretical energy densities up to twelve times higher than lithium-ion cells, delivering unprecedented efficiency with zero operational emissions.

Despite their theoretical advantages, metal–air batteries have yet to achieve widespread commercial viability due to several critical obstacles. Current high-performance catalysts primarily depend on expensive precious metals, such as platinum and ruthenium, rendering them economically unfeasible for mass production and large-scale deployment. Furthermore, most existing catalyst materials are monofunctional, efficiently driving only one of the two essential electrochemical processes—the oxygen reduction reaction (ORR) or the oxygen evolution reaction (OER)—but not both. Compounding these issues, the complex, multi-step synthesis processes required for these catalysts inflate manufacturing costs and severely restrict scalability.

Against this backdrop, a research team led by Professor Takahiro Ishizaki from the College of Engineering at Shibaura Institute of Technology, Japan, and Assistant Professor Sangwoo Chae from Nagoya University, Japan, has been working hard to find appropriate solutions for these issues. In their latest study, published in Sustainable Energy & Fuels on May 29, 2025, they report a revolutionary single-step method for creating highly effective bifunctional catalysts using abundant, low-cost materials.

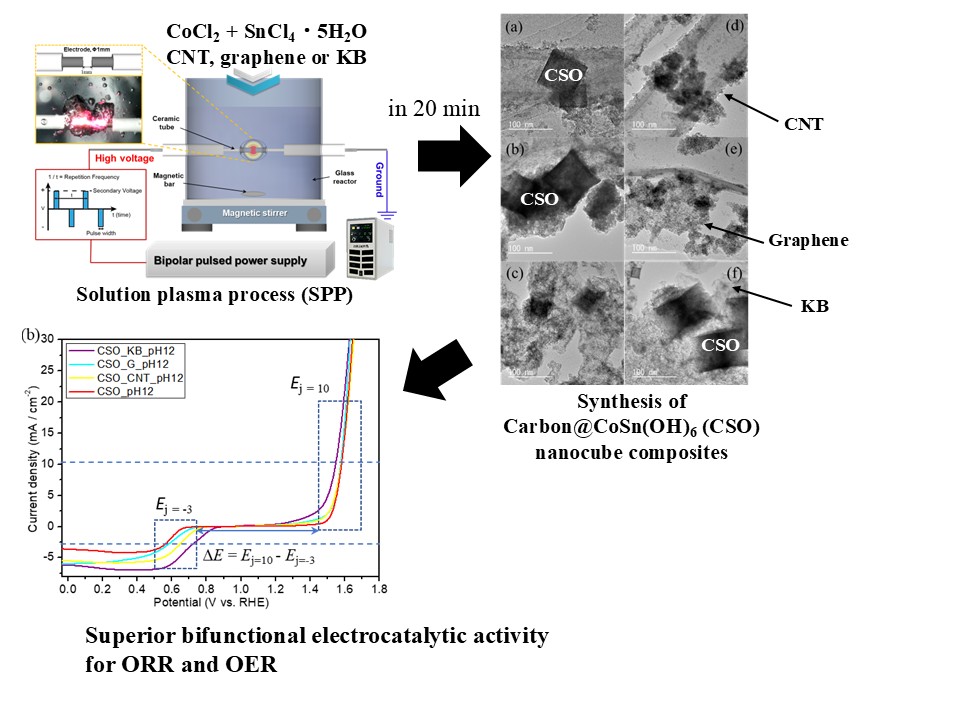

The researchers utilized the recently pioneered solution plasma process (SPP) for the synthesis, successfully creating cobalt-tin hydroxide (CoSn(OH)6) composites anchored to various carbon supports. This is a critical distinction from conventional catalyst synthesis: unlike traditional, multi-step methods that require surfactants and extensive post-processing, SPP enables rapid, single-step synthesis at room temperature under ambient atmospheric conditions. This plasma-based approach not only confers unique surface properties that significantly boost catalytic activity but also dramatically slashes manufacturing complexity and production costs.

The research team systematically produced catalysts with varied compositions and carbon structures, rigorously testing their bifunctional performance in both the oxygen reduction (ORR) and oxygen evolution (OER) reactions—the two pivotal processes determining overall battery efficiency. Their best-performing catalyst, combining CoSn(OH)6 with Ketjen Black carbon, achieved remarkable results. For oxygen evolution, it outperformed the industry-standard ruthenium oxide catalyst, requiring lower voltages to achieve the same current densities. In oxygen reduction, it exhibited performance comparable to much more expensive platinum-based catalysts while relying solely on abundant materials.

Moreover, this new catalyst proved to be quite durable, as Prof. Ishizaki remarks: “Our advanced CoSn(OH)6–Ketjen Black composite exhibited exceptional long-term stability, maintaining its superior oxygen evolution performance for over 12 hours without degradation, a crucial factor for real-world battery applications.”

Notably, the catalyst’s ability to efficiently catalyze both required reactions represents a significant advancement in the field. The researchers measured a potential gap of just 0.835 V between the two reactions, thus enabling highly efficient energy conversion. This dual functionality eliminates the need for separate catalysts, further reducing system complexity and costs.

Detailed analysis confirms that the superior catalytic performance stems from powerful synergistic interactions between the (CoSn(OH)6) nanoparticles and the carbon support. The researchers discovered that the SPP synthesis process is key: it ensures a uniform distribution of active nanoparticles across the carbon surface, which maximizes the exposure of catalytic sites while simultaneously guaranteeing excellent electrical conductivity. Furthermore, the method offers precise control over particle size and crucial surface properties, allowing for systematic optimization of catalytic activity. “This breakthrough holds profound potential to customize and manufacture high-performance, durable, and low-cost bifunctional electrocatalysts for critical energy conversion systems,” highlights Prof. Ishizaki. “It offers a truly sustainable material alternative to commercially used precious metal-based catalysts.”

The implications of this work are far-reaching, promising a revolution across the energy sector.

Metal–air batteries powered by these newly developed catalysts could fundamentally transform energy storage for electric vehicles, offering a significantly longer range and faster charging capabilities while simultaneously reducing overall costs. Furthermore, the technology holds immense potential for grid-scale energy storage, which is crucial for the efficient integration of intermittent renewable sources like solar and wind power into electrical networks. The proposed single-step synthesis method offers equally profound industrial advantages. By eliminating complex, multi-step processing and reliance on expensive raw materials, manufacturers can produce these high-performing catalysts at a fraction of the current cost. Moreover, the ability to synthesize these materials under ambient conditions drastically reduces energy consumption and environmental impact compared to conventional high-temperature, high-pressure methods currently used in battery and catalyst production.

Overall, this research represents a crucial and transformative step toward achieving economically viable clean energy storage on a global scale, poised to significantly accelerate the essential transition away from fossil fuels in the transportation and energy sectors.

Title: Towards sustainable and scalable catalysts for metal–air batteries

Caption: In this study, researchers developed a straightforward plasma-based process to produce a composite of carbon and cobalt-tin hydroxide. Under the right synthesis conditions, the resulting material exhibits exceptional properties for metal–air batteries, paving the way to more sustainable and efficient energy storage for transportation.

Credit: Professor Takahiro Ishizaki from Shibaura Institute of Technology, Japan

Source Link: https://pubs.rsc.org/en/content/articlelanding/2025/se/d5se00370a

License Type: CC BY-NC 3.0

Usage restrictions: You are free to share and adapt the material. Attribution is required.

Reference

|

Title of original paper: |

Single-step solution plasma synthesis of bifunctional CoSn(OH)6–carbon composite electrocatalysts for oxygen evolution and oxygen reduction reactions |

|---|---|

|

Journal: |

Sustainable Energy & Fuels |

|

DOI: |

Additional infotmation for EurekAlert

|

Latest Article Publication Date: |

29 May 2025 |

|---|---|

|

Method of Research: |

Experimental study |

|

Subject of Research: |

Not applicable |

|

Conflicts of Interest Statement: |

There are no conflicts of interest to declare. |

Authors

About Shibaura Institute of Technology (SIT), Japan

Shibaura Institute of Technology (SIT) is a private university with campuses in Tokyo and Saitama. Since the establishment of its predecessor, Tokyo Higher School of Industry and Commerce, in 1927, it has maintained “learning through practice” as its philosophy in the education of engineers. SIT was the only private science and engineering university selected for the Top Global University Project sponsored by the Ministry of Education, Culture, Sports, Science and Technology and had received support from the ministry for 10 years starting from the 2014 academic year. Its motto, “Nurturing engineers who learn from society and contribute to society,” reflects its mission of fostering scientists and engineers who can contribute to the sustainable growth of the world by exposing their over 9,500 students to culturally diverse environments, where they learn to cope, collaborate, and relate with fellow students from around the world.

Website: https://www.shibaura-it.ac.jp/en/

About Professor Takahiro Ishizaki from SIT, Japan

Professor Takahiro Ishizaki received his Ph.D. from Waseda University in 2004. He currently serves as Professor in the Department of Materials Science and Engineering, College of Engineering, Shibaura Institute of Technology, Japan. His main research interests are surface engineering and the fabrication of functional energy materials. He has over 100 scientific publications to his credit.

Funding Information

This work was supported by the Strategic International Collaborative Research Program (SICORP) (grant number JPMJSC18H1) from the Japan Science and Technology Agency (JST), Grant-in-Aid for Scientific Research (B) (No. 24K01182), and Grant-in-Aid for Early-Career Scientists (No. 23K13565) from the Japan Society for the Promotion of Science (JSPS)