Urban Infrastructure Renewal: Sustainable Circulating Mixing for Urban Pile Removal

- Research

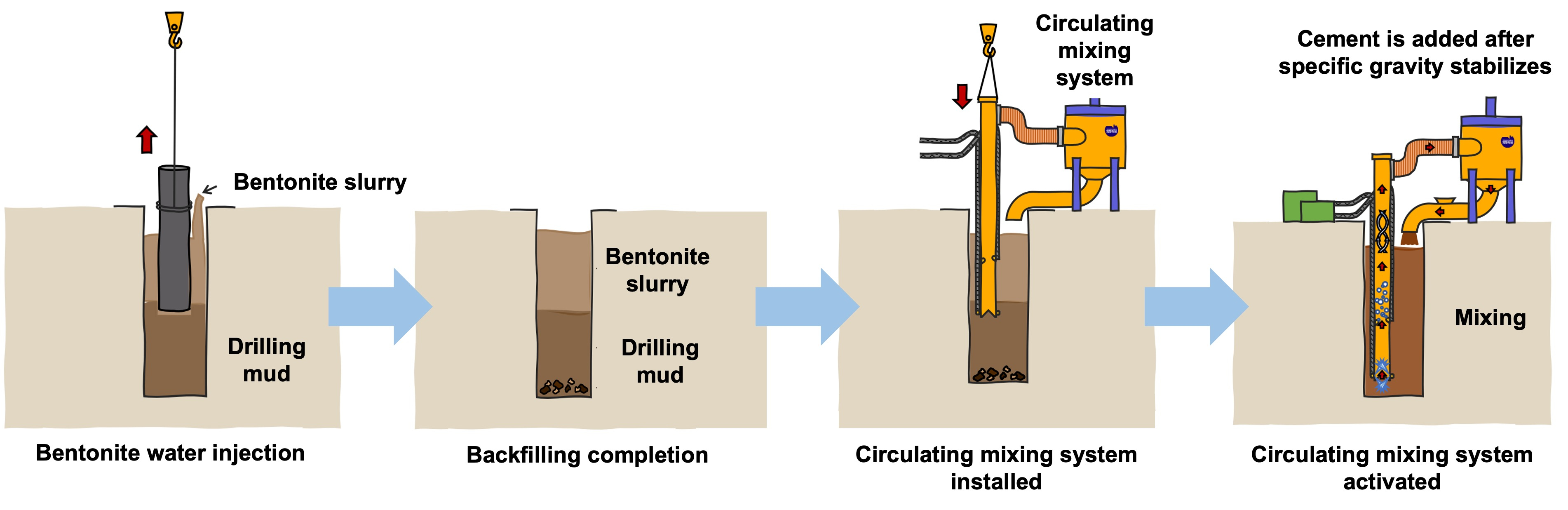

Researchers propose an approach that pumps backfill material from the borehole bottom, showcasing remarkable uniformity throughout the entire depth

Conventional borehole backfilling suffers from various technical limitations, making infrastructure demolition and renewal difficult. In an innovative development, researchers from Shibaura Institute of Technology have proposed a novel circulating mixing method that pumps backfill material from the bottom of boreholes with unprecedented uniformity throughout the entire depth. This technology can revolutionize urban construction and renewal projects, and disaster prevention and mitigation.

Title: Construction procedure for the circulating mixture method

Many developed nations are facing the simultaneous aging of infrastructure built during periods of rapid economic growth. Japan has reached a critical turning point where numerous buildings and structures constructed in the post-war boom era now require demolition and renewal. The catalyst intensified dramatically after the 2011 Great East Japan Earthquake, which exposed vulnerabilities in structures failing to meet modern disaster prevention standards, leading to sharply increased demolition activity in urban areas.

When structures are demolished, the foundation piles must be removed and classified as industrial waste, yet conventional backfilling methods consistently produce an uneven distribution of material throughout the borehole depth. This technical limitation creates serious risks, including ground settlement, structural tilting of adjacent buildings, and misalignment of newly installed foundations. As a result, the critical backfilling process lacks scientific rigor and quality control mechanisms.

In a recent breakthrough, a team of researchers led by Professor Shinya Inazumi from Shibaura Institute of Technology, Japan, has developed a novel method that can ensure uniform backfilling throughout the entire borehole depth, addressing both immediate safety concerns and long-term infrastructure sustainability. Their innovative findings were made available online on October 15, 2025 and have been published in Volume 29 of the journal Cleaner Engineering and Technology on December 1, 2025.

The proposed circulating mixing method was validated through model tests, field experiments, and advanced numerical simulations using the moving particle semi-implicit (MPS) method within a computer-aided engineering (CAE) framework. These tests demonstrated exceptional uniformity with a coefficient of variation of only 0.036, approximately ten times better than conventional soil improvement methods that typically range from 0.3 to 0.5. In addition, the field tests on 15-meter-deep boreholes confirmed that all samples exceeded the target strength of 1,500 kN/m² with no detection of structurally inadequate weak zones.

“Most significantly, our approach allows engineers to optimize process parameters and improve quality control by employing advanced MPS-CAE computer simulations to predict mixing behavior before construction. Moreover, it addresses Japan's urgent infrastructure renewal needs while promoting sustainability by preventing soil degradation, reducing construction waste, and minimizing the carbon footprint of urban projects,” says Prof. Inazumi.

The findings reveal that this method is especially valuable when constructing high-rise buildings on sites with existing pile foundations, where improperly backfilled boreholes could compromise the stability of new structures worth millions of dollars. Notably, the proposed method prevents ground settlement and structural tilting that could lead to catastrophic failures during seismic events, addressing critical safety concerns in earthquake-prone regions.

“Our study establishes a new standard for geotechnical engineering in urban redevelopment with potential worldwide applications, particularly in cities facing aging infrastructure challenges. In densely populated metropolitan areas like Tokyo, New York, or London, where numerous buildings constructed during post-war economic boom periods now require demolition and reconstruction, this technology ensures safe and efficient site preparation,” says Prof. Inazumi.

The amalgamation of engineering techniques with numerical simulation in the proposed method enables the industry to shift from reactive quality assessment to proactive process optimization, improving the efficiency, safety, durability, and sustainability of urban redevelopment projects, especially in disaster-prone regions.

The paradigm shift in geotechnical engineering practice can help engineering consultancies and construction companies to reassure their clients of construction quality through pre-construction numerical analysis, enhancing transparency and accountability in urban infrastructure projects.

“Our innovative method supports sustainable urban development by minimizing construction waste and reducing the carbon footprint associated with material transportation and disposal. It further offers a pathway to improved geotechnical performance in urban infrastructure development, contributing to disaster resilience, protecting lives and property investments,” concludes Prof. Inazumi.

Reference

|

Title of original paper: |

Sustainable approach to urban pile removal through evaluation of innovative circulating mixing for urban infrastructure renewal |

|

Journal: |

Cleaner Engineering and Technology |

|

DOI: |

Additional infotmation for EurekAlert

| Latest Article Publication Date: | 1 December 2025 |

| Method of Research: |

Computational simulation/modeling |

| Subject of Research: | Not Applicable |

| Conflicts of Interest Statement: | The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. |

Authors

About Professor Shinya Inazumi from SIT, Japan

Dr. Shinya Inazumi is a Professor at the College of Engineering, Shibaura Institute of Technology, Japan. He has expertise in civil and environmental engineering, with a strong focus on geotechnical engineering. With over 300 scholarly publications on topics, such as particle-method simulations, sustainable geopolymer materials, and AI-driven urban-resilience mapping, he is recognized as a leading geotechnical researcher. He has been honored with multiple awards, including the MEXT Young Scientists’ Prize (2015), ICE Publishing Environmental Geotechnics Prize (2020), ISSN Outstanding Researcher & Golden Research Awards (2020), and a Best Paper Award at the 14th International Conference on Geotechnique, Construction Materials and Environment (2024).

Funding Information

NA