Innovative Method for Visualization and Prediction of Sedimentation in Soft-Ground Drilling

- Research

Researchers have developed a novel method to evaluate the sedimentation process during drilling in the construction of cast-in-place concrete piles.

The construction of cast-in-place concrete piles, suitable for addressing the drawbacks of soft ground in earthquake-prone areas, requires a good understanding of the sedimentation processes during drilling to maintain the properties of drilling slurry. However, the conventionally used Stokes’ law for predicting the settling time of sedimentation only produces a one-dimensional picture. Now, researchers from the Shibaura Institute of Technology developed a numerical particle-based method that provides an improved three-dimensional behavior of these processes.

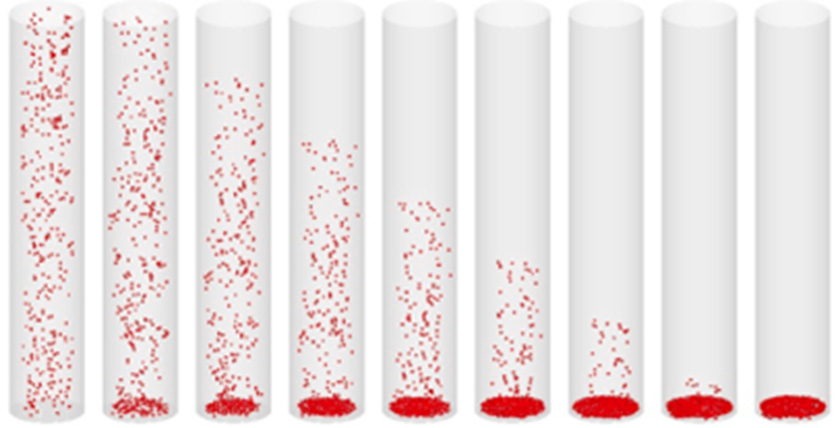

Title: Temporal changes in the sedimentation of 75-micrometer sand particles using the MPS-CAE method

Caption: The proposed method can provide deeper insights into the sedimentation process during drilling, thereby improving the efficiency and reliability of foundation construction practices in geotechnically challenging environments.

Credit: Shinya Inazumi from Shibaura Institute of Technology

https://www.sciencedirect.com/science/article/pii/S2590123024005280

License type: CC BY-NC-ND

Usage restrictions: Credit must be given to the creator. Only noncommercial uses of the work are permitted. No derivatives or adaptations of the work are permitted.

Soft ground is composed of fine particles such as clay and silt. It is particularly prevalent in coastal areas. It can significantly impact the safety and stability of dams and structures, therefore necessitating techniques for enhancing safety, strength, and bearing capacity. In Japan, where soft ground and earthquakes are common, various foundation and ground improvement methods are implemented to mitigate the harmful effects of such disasters. One such method involves the construction of cast-in-place concrete piles, which use a drilling slurry to fill borewells during excavation. This slurry protects the hole walls with its wall-making properties and pressure and serves as a replacement fluid during concrete placement, with the drilling slurry being recycled as much as possible.

During construction, the properties of the drilling slurry can deteriorate due to soil mixing and loss of base materials. Therefore, it is essential to manage properties such as specific gravity, viscosity, wall-making properties, etc. to maintain the quality of concrete piles. Even after managing these properties, issues like clogging of sand to the rebar or residual sand at the bottom can still occur, affecting the concrete fill. Consequently, it is necessary to understand the sedimentation behavior of soil particles within the drilling slurry before concrete placement. However, directly observing this process in real-time construction sites is challenging. Additionally, when predicting the settling time of sand particles during sedimentation, the traditionally used Stokes’ equation can only capture the one-dimensional motion of a single particle, failing to capture the real phenomenon.

To address this issue, a team of researchers from Japan, led by Professor Shinya Inazumi from the College of Engineering at Shibaura Institute of Technology developed a pioneering method to visualize the sedimentation process of sand in the drilling slurry. Prof. Inazumi explains, “We applied a numerical simulation method based on the Moving Particle Semi-Implicit (MPS) method that enables a detailed and accurate visualization of the three-dimensional sedimentation behavior of sand particles in drilling slurry, which directly impacts the strength and durability of the foundation.” Their study was made available online on May 15, 2024, and published in the journal Results in Engineering in June 2024.

In their study, the researchers modeled the drilling slurry and the sand particles using the MPS method to three-dimensionally reproduce the settling process. The drilling slurry and the sand particles were treated as Bingham fluid, a non-Newtonian fluid that behaves as a rigid body at low stresses but flows as a viscous fluid at high stresses. This model accurately captures the flow behavior of fresh concrete. The researchers also conducted a visual assessment of the model using a computer-aided engineering (CAE) tool designed for the MPS method, collectively called MPS-CAE.

The sedimentation process of 75-micrometer and 150-micrometer sand particles in the drilling slurry was visually evaluated by the MPS-CAE and the settling times for both were compared. The settling process of the 75-micrometer sand particles was evaluated to predict the longest time and that of the 150-micrometer sand particles to predict the shortest time. To test the effectiveness of the MPS method, the analysis results from the modeling were compared with a laboratory cylindrical test, designed to simulate the sedimentation process. The results showed that the predicted settling times for both cases agreed with experimental data.

The results also revealed that the MPS method produced a much more accurate, three-dimensional picture of the sedimentation process, compared to Stokes’ equation. Furthermore, the researchers applied the MPS method for visual evaluation of sedimentation in full-scale drilling slurry, in the Tone Boring Hole pile method, conducted at an actual construction site, demonstrating its practicality.

These findings reveal the utility of this method in predicting the settling process at construction sites. “By accurately simulating and managing the sedimentation process, this new technique significantly improves construction quality and efficiency. Moreover, this method minimizes environmental impact and can lead to new advanced construction technologies,” remarks Prof. Inazumi.

Looking ahead, he concludes, “This development promises to revolutionize foundation construction practices, ensuring safer and more reliable structures in areas facing geotechnical challenges.”

Reference

| Title of original paper: |

Assessing sand sedimentation in drilling slurry using particle methods for ground excavation management |

| Journal: | |

| Article link: |

Authors

About Professor Shinya Inazumi from SIT, Japan

Shinya Inazumi is currently a Professor at the College of Engineering, Shibaura Institute of Technology, Japan. He obtained his Ph.D. from Kyoto University in 2003. At SIT, he also leads the Geotechnical Engineering Laboratory. He also serves as the Representative Director of the Association for the Promotion of Geotechnical Technology. Prior to joining SIT, he also served as a Professor at the National Institute of Technology at Akashi College, till 2017 and Graduate School of Engineering at Kyoto University, till 2013. He has over 150 publications with over 500 citations. His research interests include Social Infrastructure Engineering, Civil Engineering, Geotechnical Engineering, Geo-Environmental Engineering, Geo-Disaster Engineering, Geotechnical analysis studies, Geo-Information Studies, Artificial intelligence and Computer science.

Funding Information

Not Available